CA4PRS Use in Washington State

slide 1

CA4PRS Use in Washington State

by

Jeff Uhlmeyer, State Pavement Engineer

View the PDF

Version [708 KB]

![]() You will need the Adobe

Reader to view the PDFs on this page.

You will need the Adobe

Reader to view the PDFs on this page.

slide 2

WSDOT Efforts to Mitigate Construction Impacts:

- Alternative contracting

- Rapid construction strategies

- Alternative closure windows

- Specialized materials

- Training and education

slide 3

CA4PRS: A tool for estimating contractor productivity

- Estimates contractor productivity given:

- Traffic closure window

- Lane availability and use for construction

- Construction materials

- Pavement structure

- Scheduling constraints

- Resource constraints

slide 4

slide 5

| Construction Window: | Weekend Closure (55 hours/weekend) |

|---|---|

| Working Method: | Sequential Single Lane (T2) |

| Section Profile: | PCCP: 13.0 inches, New Base: 0.0 inches |

| Curing Time: | 8 hours |

| Objective (lane-miles): | 2.22 |

| Maximum Possible (lane-miles) | 0.57 |

| Maximum Possible (c/l-miles) | 0.57 |

| Construction Windows Needed to Meet Objective: | 3.90 |

| Resource | Allocated | Utilized |

|---|---|---|

| Demolition Hauling Truck (per hour per team) | 6.0 | 6.0 |

| Base Delivery Truck (per hour) | 8.0 | 0.0 |

| Batch Plant (cu-yd/hour) | 200.0 | 77.1 |

| Concrete Delivery Truck (per hour) | 12.5 | 10.3 |

slide 6

CA4PRS productivity estimates can assist:

- Evaluating different closure scenarios

- Selecting most appropriate closure strategy

- Identifying equipment and material requirements

- Identifying ranges of potential contractor productivity

- Verifying contractor productivity estimates

slide 7

CA4PRS and WSDOT

- Is CA4PRS appropriate for projects in Washington State?

- At what level of project planning is CA4PRS applicable?

- How should WSDOT use CA4PRS?

slide 8

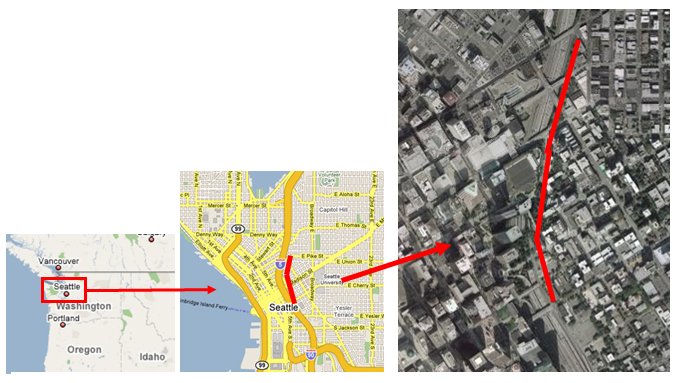

I-5 Olive to James Rehabilitation

- Reconstructed outside lanes, drop lanes and ramp segments

- Removed of 6,500 yd3 of material

- Placed of 2,500 tons of HMA base and 5,640 yd3 concrete pavement

- Four 55-hour weekend closures

slide 9

Project Location

slide 10

slide 11

Paving Quantities and Stage Paving Lengths (lane-miles)

| Stage | Fixed Form Paving |

Slipform Paving (yd3) |

Total Paving Quantity (yd3) |

Stage Psuedo Length (lane-miles) |

|---|---|---|---|---|

| Stage 1 | 776 | 1100 | 1876 | 0.74 |

| Stage 2 | 572 | 995 | 1567 | 0.62 |

| Stage 3 | 488 | 808 | 1296 | 0.51 |

| Stage 4 | 364 | 540 | 904 | 0.36 |

| Total Paving Quantity: 2.22 (yd3) |

||||

slide 12

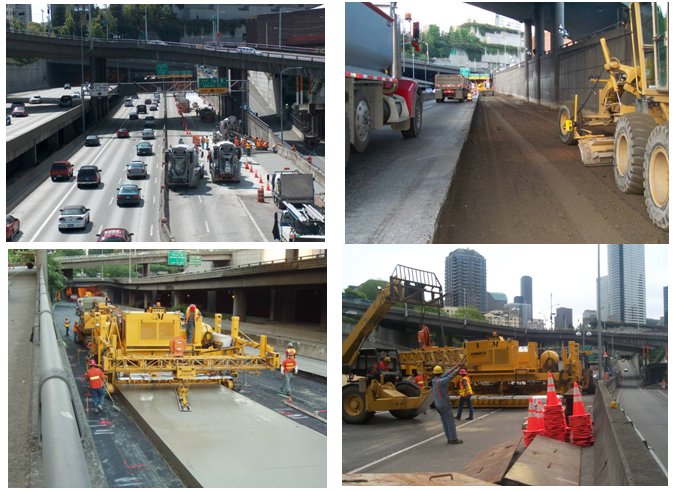

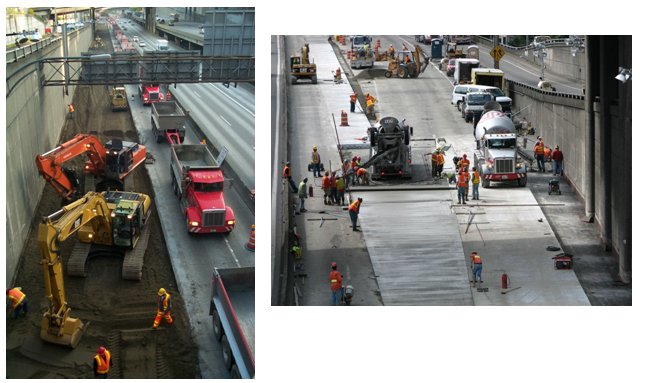

Construction Sequence

- Establish traffic control and installation of construction barrier

- Demolish and remove existing pavement

- Subgrade repair

slide 13

Construction Sequence

- HMA base paving

- PCC paving

- PCC curing, sawcutting and pavement marking

- Removal of equipment and traffic control

slide 14

Job Specific Constraints

- Narrow work zone

- Slipform paving machine constraints

slide 15

Job Specific Constraints

- Paving lane access

- Adjacent commercial development

- Site access

slide 16

Construction Process

slide 17

Job Specific Constraints

slide 18

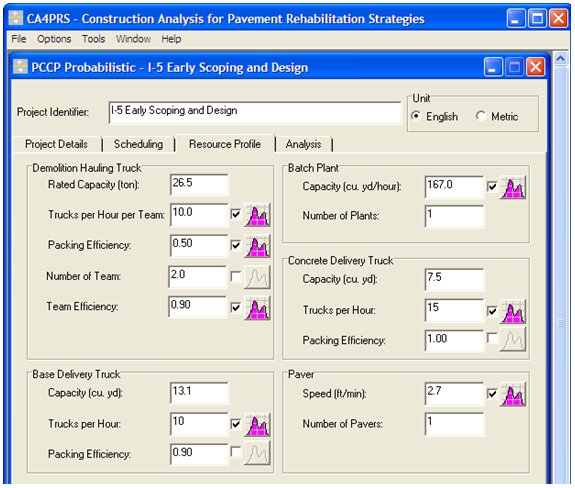

1st Analysis: CA4PRS Applicability For Early Scoping and Design Evaluation

- Sufficient project information available for CA4PRS estimate development

- Input parameters established from similar and previously completed projects

- Slipform and fixed form operations combined into a pseudo paving speed of 2.67 ft/min

slide 19

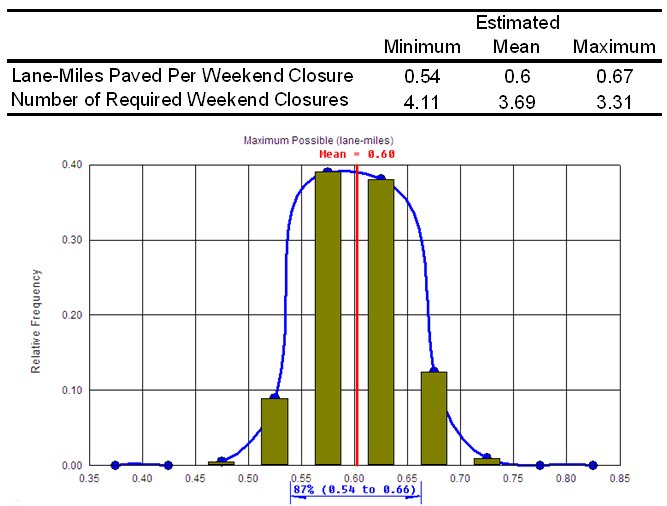

1st Analysis: CA4PRS Applicability For Early Scoping and Design Evaluation

slide 20

slide 21

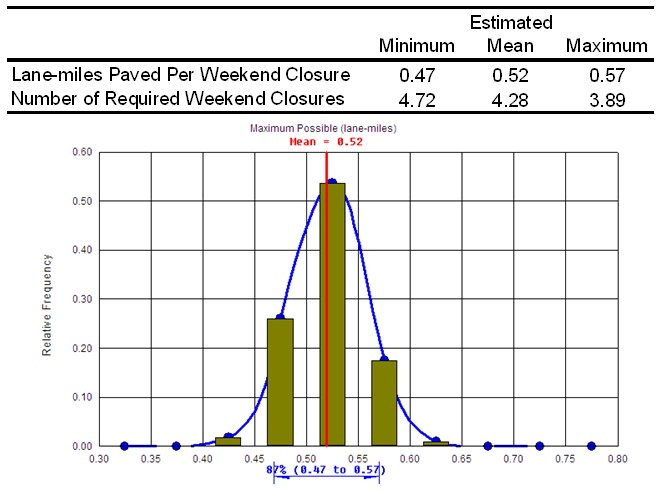

2nd Analysis: CA4PRS Applicability For Post-Award Pre-Construction Evaluation

- Contractor schedules used to refine:

- Construction sequencing

- Activity lag times

- Mobilization and demobilization times

slide 22

slide 23

CA4PRS Guidelines

- Base decisions on probabilistic outputs

- Maintain a database of construction productivity

- Assign triangular distributions to probabilistic inputs if distribution data is unavailable

- Round estimated construction windows up to nearest whole number

slide 24

Evaluation Conclusions

- CA4PRS can be used during early scoping and design as well as post-award pre-construction verification

- Produce estimates from probabilistic analysis

- CA4PRS estimates are reasonably accurate with generic input parameters

slide 25

Evaluation Conclusions

- Input parameter selection determines estimate accuracy

- Input parameter variation may not encompass productivity for constrained projects

- CA4PRS requires further refinement to make it more generic and flexible

slide 26

CA4PRS at UW

- The University of Washington graduates 120 civil engineers each year to meet regional demand

- CEE 404 Infrastructure Construction

- Transportation project development and construction

- CA4PRS combines real-world information with project planning

slide 27

CA4PRS Analysis

I-5 Bow Hill,

Crack and Seat Overlay

slide 28

Project Parameters

- Crack and Seat and Overlay two NB lanes of I-5 between MP 231.8 to MP 243.33 (south of Bellingham, WA)

- 20 lane-miles

- Classified as a rural freeway with a 23,000 ADT and 9% trucks

- Two 12-ft lanes with a 4 feet inside and a 10 feet outside shoulders

- Constructed in 1966 using 9 inches of JPCP

- Rehabilitated in 1993 with a 4 inch HMA overlay and sub-sealing due to considerable faulting

slide 29

Construction Process

- Expose PCCP pavement by milling the 4 inch overlay Shoulders remain as is, no milling

- Divert traffic on SB I-5 lanes using counter-flow traffic operations

- Overlay the crack and seat slabs with 8 inches of HMA pavement in three lifts: 4 inch initial lift followed by two additional 2 inch lifts

slide 30

Construction Scenarios

- Baseline. All operations (milling, crack and seat and the full 8 inch overlay paving) are accomplished during each closure.

- Baseline but with 2 Milling teams and 2 paving teams. It is likely that 2 milling and paving teams (e.g., 2 milling machines and 2 paving machines) can operate in the project area.

- Just milling 4.2 inches of mainline pavement with 2 milling teams. An obvious breakpoint in the work would be after milling off all the HMA in the mainline.

- Just milling 4.2 inches of mainline pavement with 4 milling teams 50% efficiency. The lower efficiency is an attempt to account for the added complexity of operations with 4 milling teams.

- Crack and seat plus a 4.2 inch overlay to bring the mainline pavement height up to the existing shoulder height. This operation would follow the "just milling" one.

- Overlay the final 4.0 inches for the mainline and shoulders. This operation would follow the "crack and seat plus 4.2 inches overlay" one.

slide 31

| Input | Value | Distribution/Comments |

|---|---|---|

| Mobilization | 1.0 hour | None – Deterministic. Set traffic control, mobilize equipment. |

| Demobilization | 2.0 hours | None – Deterministic. |

| Half Closure Traffic Switch | 0.5 hours | Triangular (min = 0.25 hrs, max = 0.75 hrs). Time to switch traffic if only closing 1 lane in NB direction. |

slide 32

| Input | Value | Distribution/Comments |

|---|---|---|

| Milling and Hauling | ||

| Number of Team | 1 team | None – Deterministic. |

| Team Efficiency | 0.8 | Triangular (min = 0.7, max = 0.9) |

| Milling Machine | ||

| Machine Class | Large | Choices are large, medium, small |

| Material Type | AC – Hard | Good choice for hard rock in western WA |

| Efficiency Factor | 0.7 | Triangular (min = 0.6, max = 0.8) Tooth replacement may affect downtime. |

| Hauling Truck | ||

| Rated Capacity | 18.0 tons | None – Deterministic. |

| Trucks/hr/team | 13/hr | Triangular (min = 11/hr, max = 15/hr) |

| Packing Efficiency | 1 | None – Deterministic. |

slide 33

| Input | Value | Distribution/Comments |

|---|---|---|

| Batch Plant | ||

| Capacity | 350 t/hr | Triangular (min = 300 t/hr, max = 400 t/hr) |

| Number of Plants |  |

None – Deterministic. |

| HMA Delivery Truck | ||

| Capacity | 16 tons | None – Deterministic. |

| Trucks per Hour |  |

Triangular (min = 11/hr, max = 15/hr) |

| Packing Efficiency |  |

None – Deterministic. |

| Paver | None | N/A (no base material) |

| Non-paving speed | 15 mph | |

slide 34

| Input | Value | Distribution/Comments |

|---|---|---|

| Construction Window | weekend nighttime continuous |

55-hour weekend closures 10-hour nighttime closures 168-hour continuous week-long closures |

| Section Profile | 2-2-4 | Bottom lift: 4 inches (0.33 mph for paver) |

| Change in Roadway Elevation | +4 inches |

The new roadway will be 4 inches higher than the old after milling and overlaying. |

slide 35

| Input | Value | Distribution/Comments |

|---|---|---|

| Shoulder Overlay | Simultaneous | Shoulders already contain 4.2 inches of HMA. They will be overlayed with

an additional 4 inches of HMA. |

| Working Method |

Full closure | Only allowed option in CA4PRS. |

| Cooling Time Analysis |

User Spec. |

Time calculated in MultiCool and manually entered |

| Lane Widths | ||

| No. of Lanes | 2 | |

| Lane Widths |

12 ft each | Travelled lanes only |

slide 36

| Input | Value |

|---|---|

| Start Time | 1000, 7/15/2011 |

| Environmental Conditions | |

| Ambient Air Temp. | 60°F |

| Average Wind Speed | 5 mph |

| Sky Conditions | Clear&Dry |

| Latitude | 44° North |

| Existing Surface | |

| Material Type | PCC |

| Moisture Content | N/A |

| State of Moisture | N/A |

| Surface Temp. | 55°F |

slide 37

| Input | Value |

|---|---|

| Mix Specifications | |

| Mix Type | Dense Graded |

| PG Grade | 70-22 |

| Delivery Temp. | 300°F |

| Stop Temp. | 130°F |

| Lift Thicknesses | |

| 1st 4 inches of HMA | Paved as one 4-inch lift |

| 2nd 4 inches of HMA | Paved as two 2-inch lifts |

slide 38

| Scenario | Closure Production | Construction Windows | Total Working Hours |

|---|---|---|---|

| 14-hour nighttime closures | Not possible | N/A | N/A |

| 55-hour weekend closures | 1.01 lane-miles | 19.71 | 1084.3 hrs |

| Continuous closure | 38 days to pave 20 lane-miles | 38 days to pave 20 lane-miles | 905.4 hrs |

| Constraints: Milling Machines, HMA trucks | |||

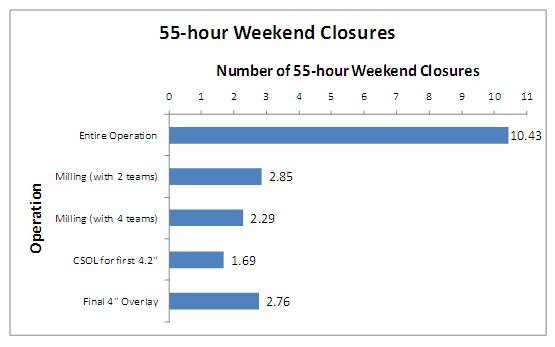

slide 39

| Scenario | Closure Production | Construction Windows | Total Working Hours |

|---|---|---|---|

| 14-hour nighttime closures | Not possible | N/A | N/A |

| 55-hour weekend closures | 1.92 lane-miles | 10.43 | 573.7 hrs |

| Continuous closure | 21 days to pave 20 lane-miles | 21 days to pave 20 lane-miles | 498.3 hrs |

| Constraints: HMA batch plant, Milling machine | |||

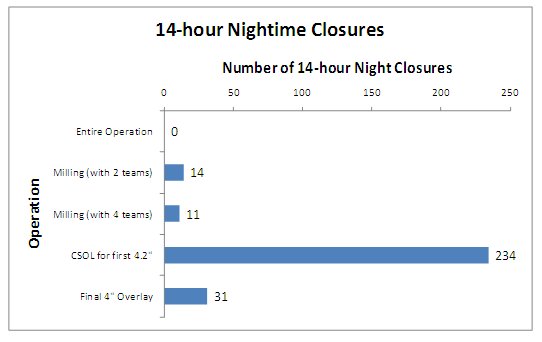

slide 40

| Scenario | Closure Production | Construction Windows | Total Working Hours |

|---|---|---|---|

| 14-hour nighttime closures | 1.47 lane-miles | 13.60 | 190.4 hrs |

| 55-hour weekend closures | 7.01 lane-miles | 2.85 | 156.9 hrs |

| Continuous closure | 7 days to mill 20 lane-miles | 7 days to mill 20 lane-miles | 498.3 hrs |

| Constraints: Milling machine | |||

slide 41

| Scenario | Closure Production | Construction Windows | Total Working Hours |

|---|---|---|---|

| 14-hour nighttime closures | 1.84 lane-miles | 10.89 | 52.5 hrs |

| 55-hour weekend closures | 8.75 lane-miles | 2.29 | 125.7 hrs |

| Continuous closure | 6 days to mill 20 lane-miles | 7 days to mill 20 lane-miles | 498.3 hrs |

| Constraints: Milling machine | |||

slide 42

| Scenario | Closure Production | Construction Windows | Total Working Hours |

|---|---|---|---|

| 14-hour nighttime closures | 0.09 lane-miles | 233.34 | 3266.7 hrs |

| 55-hour weekend closures | 11.82 lane-miles | 1.69 | 93.0 hrs |

| Continuous closure | 4 days to pave 20 lane-miles | 4 days to pave 20 lane-miles | 88.7 hrs |

| Constraints: Batch plant | |||

slide 43

| Scenario | Closure Production | Construction Windows | Total Working Hours |

|---|---|---|---|

| 14-hour nighttime closures | 0.65 lane-miles | 30.99 | 733.9 hrs |

| 55-hour weekend closures | 7.25 lane-miles | 2.76 | 151.7 hrs |

| Continuous closure | 6 days to pave 20 lane-miles | 6 days to pave 20 lane-miles | 157.2 hrs |

| Constraints: Batch plant | |||

slide 44

slide 45

slide 46

slide 47

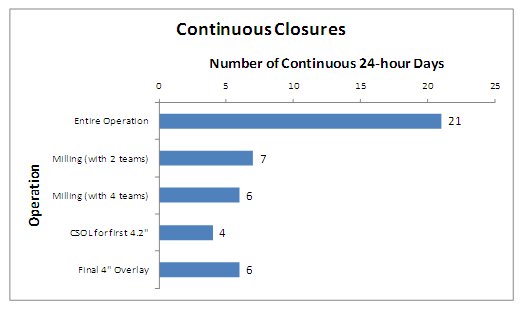

Observations

- 10-hour nighttime closures were not considered. They are less productivity than 14-hour closures

- Milling may be possible during 14-hour nighttime closures. No other modeled operation seems feasible

- No probabilistic scenarios were run but it is reasonable to add the following uncertainties to the estimates:

- 14-hour nighttime closures: ±5 days

- 55-hour weekend closures: ±1 weekend

- Continuous closures: ±2 days

slide 48

Observations

- The best possible solution is likely a combination of closure scenarios

- Milling – performed over 14 nighttime (14 hour closures)

- CSOL and overlays (8 inch total) performed over five 55 hour closures

- No traffic analysis was done at this point. Results may become clearer with traffic numbers

slide 49

Contact Information

Jeff Uhlmeyer, State Pavement Engineer

Washington State Department of Transportation

360-709-5485

uhlmeyj@wsdot.wa.gov